About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

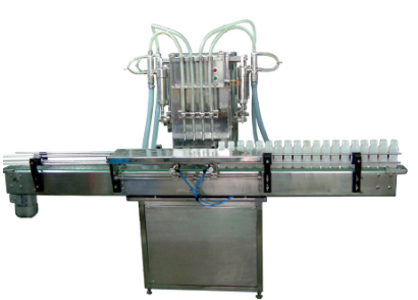

LIQUID FILLER ( LIQUID FILLING MACHINE )

- home

- LIQUID FILLER ( LIQUID FILLING MACHINE )

LIQUID FILLER ( LIQUID FILLING MACHINE )

INTRODUCTION :

The Volumetric Liquid Filling Systems from Lucas

Electronics are designed for completely automatic, multiple

position, in-line dispensing of liquids and pastes in volumes ranging from 5

ml to 5 liters per cycle. Available in 2, 4, 6, or 8 nozzle configurations

to match specific production requirements. Dual lane option available to

increase production by 100% while preserving valuable line space. Precision

bored, heavy-walled metering cylinders dispense product at accuracies up to

+/- 0.25%. All product contact parts constructed of stainless steel/food

grade plastics for sanitary operations or use with corrosive materials.

Available with motorized conveyor and indexing package for integrated

container handling and positioning. No Container/No Fill feature detects

missing or dispositional containers to prevent waste and product spillage.

Unique variable, separate speed control and actuator of a dual-stage fill

provides precise "no spill" control for top-off applications or filling

difficult products. Versatile Programmable Logic Controller (PLC) ensures

reliable, repeatable control with minimal operator intervention.

APPLICATION :

The piston type flow volumetric filling machines are best suited for filling

liquids with low to medium viscosity; with the exception of our rotary

fillers which can fill heavy viscosity products. Our timed flow volumetric

fillers are highly accurate, very sanitary, and adaptable for molten

products, and they can be used to fill light foamy products as well. These

fillers are most ideal for filling light liquid products at higher speeds.

Some example products our timed flow volumetric filling machinery can fill

are: water, fruit juice, wine, tea, and other non carbonated aqueous

beverages, food coloring, sauces, syrups, light shampoos, urine, blood,

cough syrup, douches, enemas, perfume, essential oils, aroma therapy,

cleansers and specialty chemicals, solvents, alcohol, thin paints and paint

thinners, and inks. Cleaning is a simple process, no tools are required. All

of our timed flow volumetric filling machines are based on heavy-duty

stainless steel frames with all contact parts made of food grade materials.

Salient Features :

The volumetric liquid filling systems from Lucas Electronics are designed

for complete automatic, multiple position, in-line dispensing of liquids and

pastes in volumes ranging from 500 ml to 5 litres per cycle. Available in 2,

4, 6, or 8 nozzle configurations to match specific production requirements.

Dual lane option available to increase production by 100% while preserving

valuable line space. Precision-bored, heavy-walled metering cylinders

dispense product at accuracies up to +/- 0.25%. All product contact parts

constructed of stainless steel/food grade plastics for sanitary operations

or use with corrosive materials. Available with motorized conveyor and

indexing package for integrated container handling and positioning. No

Container/No Fill feature detects missing or dispositional containers to

prevent waste and product spillage. Unique variable, separate speed control

and actuator of a dual-stage fill provides precise "no spill" control for

top-off applications or filling difficult products. Versatile Programmable

Logic Controller (PLC) ensures reliable, repeatable control with minimal

operator intervention.

Operations :

Master Seal's automatic liquid filling machines are used in filling plastics

bags with granular or dusty products. The bags start as a roll of film which

is loaded on the back of the filling unit, and fed through a series of

rollers and forming chutes. Once the film is formed into the bag shape, it

is heat-sealed closed. Simultaneously the product measured by weight or

volume, and fed into the bag. The full bag is conveyed to the next process

in line.

Maintenance :

Cleaning is a simple process, no tools are required. All of our timed flow

volumetric filling machines are based on heavy-duty stainless steel frames

with all contact parts made of food grade materials.

| Models | LE-FFS-50G | LE-FFS-250G | LE-FFS-500W | LE-FFS-1000G |

|---|---|---|---|---|

| Pouch Size | 60 mm x 80 mm | 100 mm x 120 mm | 150 mm x 180 mm | 225 mm x 250 mm |

| Speed | 40 to 60Pouches/m | 30 to 40 Pouches/m | 20 to 25 Pouches/m | 12 to 20 Pouches/m |

| Power | 1 k.w. | 1.6 k.w. | 1.5 k.w. | 2 k.w. |

| Packing Material | All Laminated Films | All Laminated Films | All Laminated Films | All Laminated Films |

PUMP FILLER

Model F Pump Filler

The Model F Pump Liquid Filler has been specially designed for high

speed/high cycle rate dispensing of a wide variety of liquids and other high

viscosity Products. A high capacity, positive displacement pump - operated

by an adjustable speed drive motor and clutch/brake provides accurate,

repeatable filling. A pneumatically operated, plug-rod cutoff assembly

eliminates product waste and dripping. Large capacity, 25 gal., stainless

steel hopper supplies pump with product. All filling operations of the F-400

are controlled from Lucas Electronics field proven Cerebus III microcomputer

system. Filling characteristics, such as filling amounts, equipment control,

production presets, etc., are saved together in separate Setup Programs

stored in memory. Different Setup Programs can be developed, entered, and

saved for each product…, package…, size…, or application, then recalled for

use directly at the control panel. No reprogramming necessary. Valuable

Status menu provides a variety of useful production and statistical data

right at the operator's fingertips. Dedicated Test Cycle menu allows easy

testing and adjustment of key components. Function key selected "Run

Screens" summarize major production, statistical, and operational data.