About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

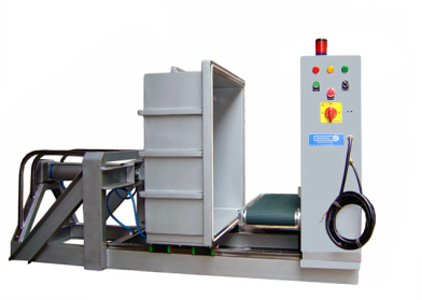

VACUUM SEALER / NITROGEN SEALER ( VACUUM SEALING MACHINE )

- home

- VACUUM SEALER / NITROGEN SEALER ( VACUUM SEALING MACHINE )

VACUUM SEALER / NITROGEN SEALER ( VACUUM SEALING MACHINE )

Salient features :

Machine designed to remove atmospheric impurities by pumping out the air

completely during packaging. The system of nitrogen gas flushing to preserve

edible stuff from contamination by germs and bacteria Internal electronic

components protected thoroughly from internal sparking and dust

contamination Vacuum and flushing processes can be done simultaneously or

individually before sealing.

Select the right vacuum packaging

machine for your application. :

Lucas Electronics is a leading manufacturer of top-quality special vacuum

packaging machines – offers an extremely wide product range spanning more

than 25 different vacuum packaging machines. The standard models of manual

table-top machine to stand-alone appliances through to fully-automated tray

sealer, Standup models are packaging of large batch quantities – the ideal

solution for every application and Vertical models are suitable for heavy

duty in large applications. All machines are extremely easy to operate,

excellently made and a great value for money. What’s more, a host of options

are available for all machines and customized solutions can be provided upon

request and consultation. Semi and fully-automated machines are climbing

higher output, for both large and also increasingly for small and medium

sized organizations.

We have made Jumbo Vacuum machines up to 400 kg for Reliance

Industries Ltd.

We can make any type of Vacuum sealing machine as per customer

requirement

Lucas Electronics Impulse Heat Sealing machines, Vacuum

sealers, Gas Vacuum Sealers, Constant heat sealers, Single Shuttle and Dual

Shuttle Sealers, and long line Feed through Heat Sealers are designed for

sealing a wide range of plastic pouch and heavy barrier bag materials in

seal widths up to 1500 mm. There are many reasons for vacuum packaging a

product - reduces static electricity, maintains sterility, protects from

corrosion, extends shelf life, packages for product safety, security and

more. We will be happy to assist you in identifying the packaging machine

that will work best for your heat sealing applications. Our valid table heat

sealers for medical packaging provide the perfect seal every time.

Repeatable and reliable control of temperature, time and pressure. Heavy

duty industrial sealer provides ability to seal, vacuum or use modified

atmosphere packaging operations. Our clean room friendly vacuum sealers are

known worldwide for vacuum packaging electronics.

We have supplied several vacuum sealers to Reliance Industries at

Patalganga Unit for packing short-cut fiber. The capacity of the vacuum

sealer is 25 to 400 kg in one shot.

Applications :

- Used to preserve

- Edibles - dry fruits, grains, pulses

- Spices, Pickles, oily eatables

*medicines, chemicals, hygroscopic powder, spare parts, and materials prone to corrosion due to moisture

* - applicable in LE-008N - Gas Flushing system

| Pneumatic Models | LE-006S | LE-007V | LE-008N | LE-009V+N | LE-009V+N(PLC) |

|---|---|---|---|---|---|

| No.Of Cycles / Hr | 900 Max | 600 Max | 700 Max | 500 Max | 600 Max |

| Input Voltage | 220/240 V AC, 50 Hz. | 220/240 V AC, 50 Hz. | 220/240 V AC, 50 Hz. | 220/240 V AC, 50 Hz. | 220/240 V AC, 50 Hz. |

| Type Of Sealing | Impulse / DH | Impulse / DH | Impulse / DH | Impulse / DH | Impulse / DH |

| Sealing Width | 5mm / 15mm | 5mm / 15mm | 5mm / 15mm | 5mm / 15mm | 5mm / 15mm |

| Sealing Length | 400mm max. | 400mm max. | 400mm max. | 400mm max. | 400mm max. |

| Power Consumption | 300 watts | 500 watts | 300 watts | 800 watts | 900 watts |

| Vacuum | Nil | 28" Hg | 28" Hg | 28" Hg | 28" Hg |

| Displacement | Nil | 75 Lts./M in. | 75 Lts./M in. | 75 Lts./M in. | 150 Lts./M in. |

| Flushing Pressure | Nil | 10 to 25 PSI | 10 to 25 PSI | 10 to 25 PSI | 10 to 25 PSI |

| Air Pressure | 15 to 25 PSI (3 Bar) | 15 to 25 PSI (3 Bar) | 15 to 25 PSI (3 Bar) | 15 to 25 PSI (3 Bar) | 15 to 25 PSI (3 Bar) |

Construction :

- Stainless steel and aluminum housing. No sharp edges. Easy to wipe.

- PLC based control panel with 4 line LCD from CRUZET France.

- Control panel is protected thoroughly from internal sparking and dust contamination.

- Base conveyor with Teflon rollers for easy movement of the product.

- Adjustable height of the base conveyor for products having different heights.

- Entirely made from stainless steel, cast aluminum & other non-ferrous materials.

- Oil mist separator to remove the oil mist from vacuum pump exhaust.

- Manual vacuum stop button for liquids & semi-liquids.

- Can be conveyors for higher output.

- Useful for molded vacuum packaging for brick shaped packs.

Optional Features :

- Insert gas flushing unit.

- Vacuum & gas sensor control for accurate level of vacuum & gas.

- Gas pressure monitoring device for nitrogen & carbon dioxide.

- Vibrating table for compaction of the material to be packed.

- In feed & discharge roller conveyor for easy movement of product or mould.

- All stainless steel mould & formers to get the perfect brick shape for moulded vacuum packaging.

- Vacuum pump by Acme engineering.