About Us

The argument in favor of using filler text goes something like this: If you use real content in the Consulting Process, anytime you reach a review point you’ll end up reviewing and negotiating the content itself and not the design.

ConsultationContact Info

- Chicago 12, Melborne City, USA

- (111) 111-111-1111

- builder@gmail.com

- Week Days: 09.00 to 18.00 Sunday: Closed

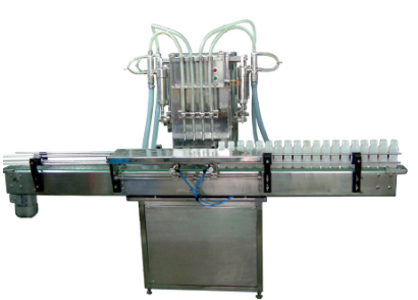

LIQUID FILLER LINEAR LF 1000 ( LIQUID FILLING MACHINE )

- home

- LIQUID FILLER LINEAR LF 1000 ( LIQUID FILLING MACHINE )

LIQUID FILLER LINEAR LF 1000 ( LIQUID FILLING MACHINE )

The Linear series liquid filling machine provides quick, accurate and advanced

straight-line filling. The horizontal position of the filling units allow for

the ability to handle a wide variety of products from free-flowing or water-thin

to viscous or thicker products. The Linear Series can accommodate up to 8

filling units

for a production rate of 100 fills/pm and Custom filling heads are available to

meet different filling requirements which can fill a wide range of container

shapes and sizes. This automatic liquid filling machine is easy to operate,

provides a quick and easy changeover.

Available with motorized conveyor and indexing package for integrated

container handling and positioning. No Container/No Fill feature detects missing

or dispositional containers to prevent waste and product spillage. Unique

variable, separate speed control and actuator of a dual-stage fill provides

precise "no spill" control for top-off applications or filling difficult

products. (Optional) Programmable Logic Controller (PLC) ensures reliable,

repeatable control with minimal operator intervention .

Quantity setting :

The filling volume can be controlled by the stroke of air cylinder

Metering Systems :

Piston, Lobe, Gear, Positive Displacement, Rolling Diaphragms

Container/Closure :

Glass, Plastic, Stoppers, Over caps, Child Resistant, Tamper Evident.

Application :

High Volume Production, Contract Packaging, Quick Changeover, OEM Applications,

Hotel Amenities, Cost Reduction, Pen Filling

Industry :

Pharmaceutical, Cosmetic, Food/Beverage, Healthcare, Personal Care, Chemical

Specialty, Veterinary

Product :

Viscous, Semi-Viscous, Water Thin, Lotion, Cream, Gel, Particulate Laden

Material, Molten Products, Shampoo, Adhesives, Laundry Detergent etc.